- Industrial Design Service from Start to Finish

- [email protected]

Sprinter Van Interior Walls: Making Utility Cozy

December 27, 2017

Sprinter Van Cabinets for the DIY Squad

March 21, 2018A Real Bed is the Difference Between a Van and a Home

UPDATE: This bed system is NOT FOR SALE. However, CreatID helped Roost Vans develop a similar bed. The FU-Kit Bed system is a mail order DIY ready bed available here. They also perform complete custom van conversions. You can see some great images on Roost Vans Instagram feed. Now for the Story:

We aimed for ultimate creature comfort with our sprinter conversion bed system.

When it comes to a bed, comfort is paramount. That’s the whole idea, isn’t it? Relax, lounge, sleep. In comfort. Amazingly, of all the bed systems we researched—located inside of Sprinters, RV’s, vans, trailers, and pop up campers—there seemed to be little importance placed on comfort.

Two inches of foam? Are you kidding me?

With our “newborn” now 14 months old, my wife and I understand the value of a good night’s sleep. We let this knowledge guide us while building our adjustable bed system for our Sprinter conversion project.

When Designing a Sprinter Van Bed System, Go Comfort First

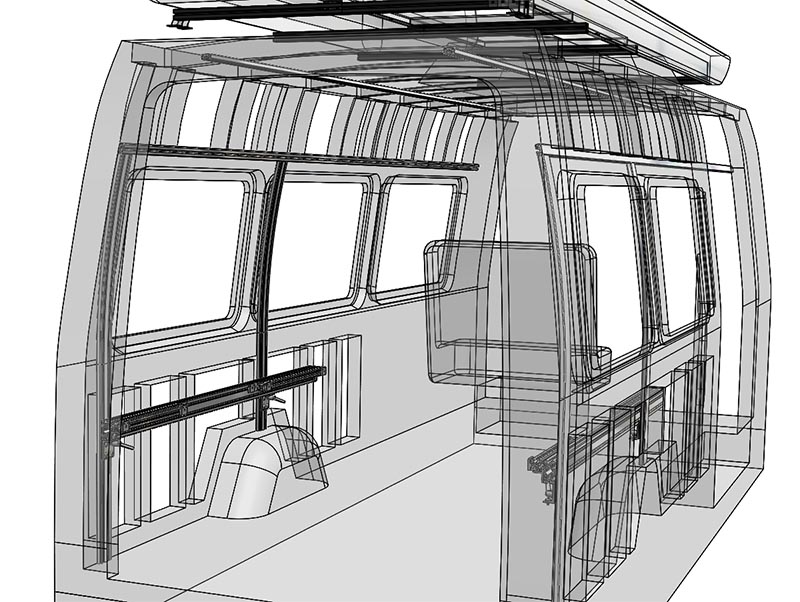

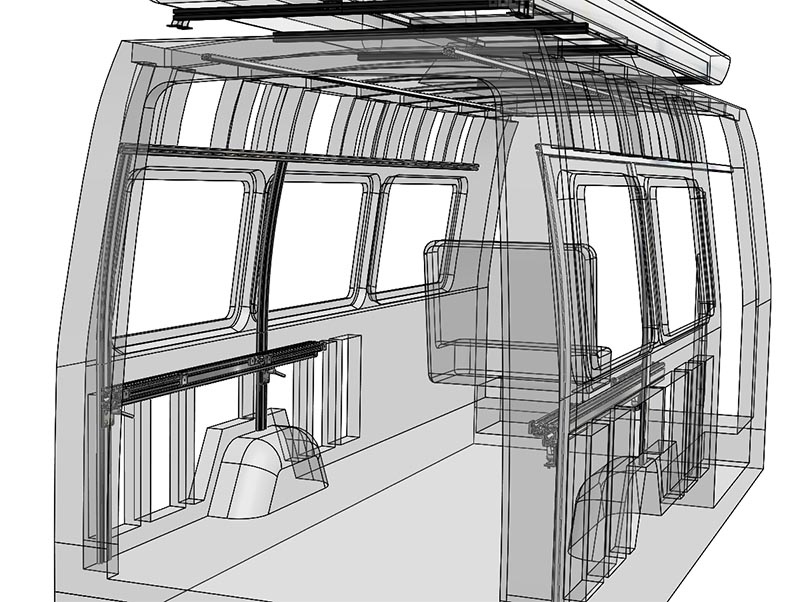

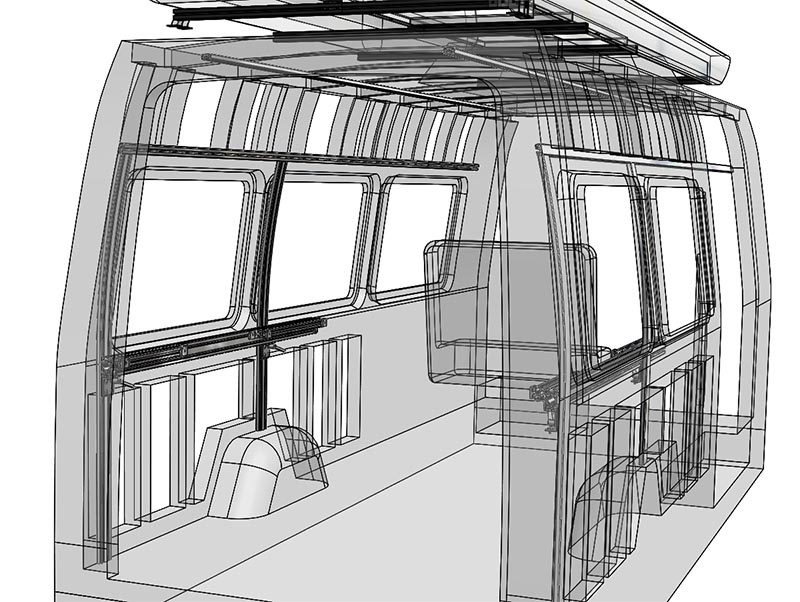

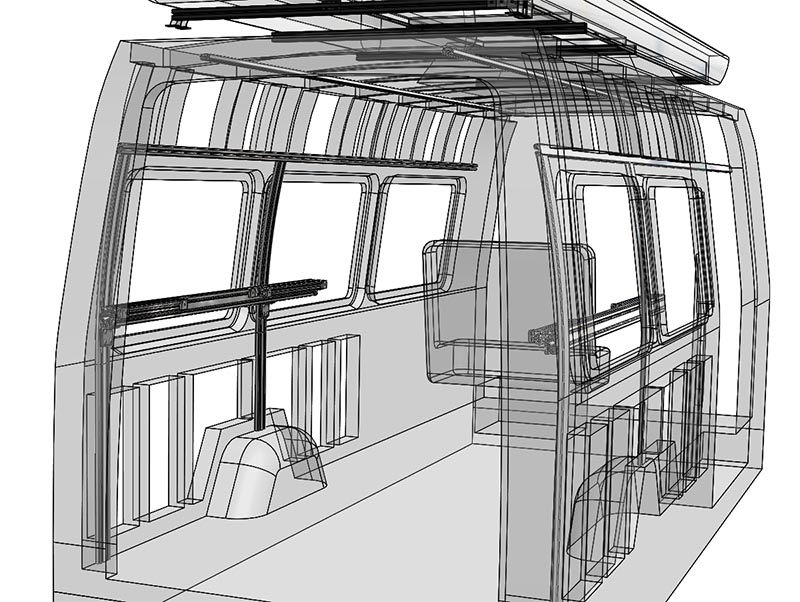

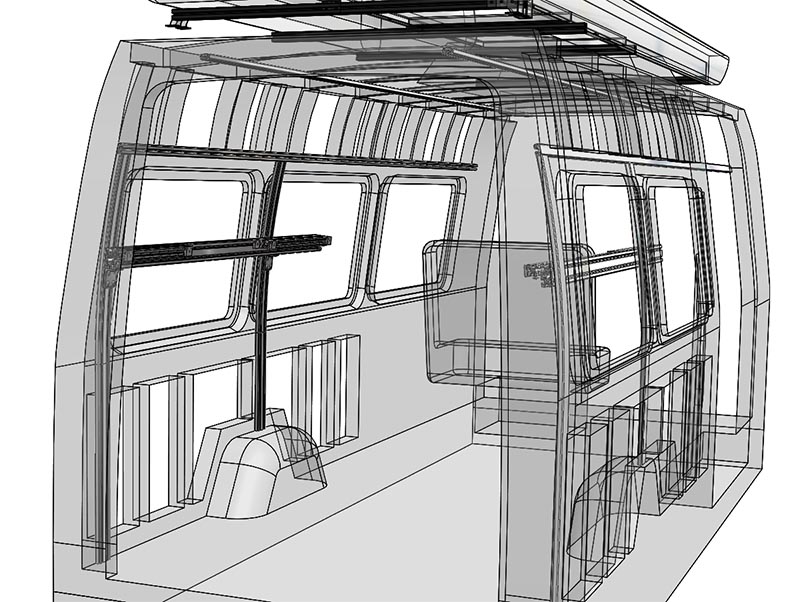

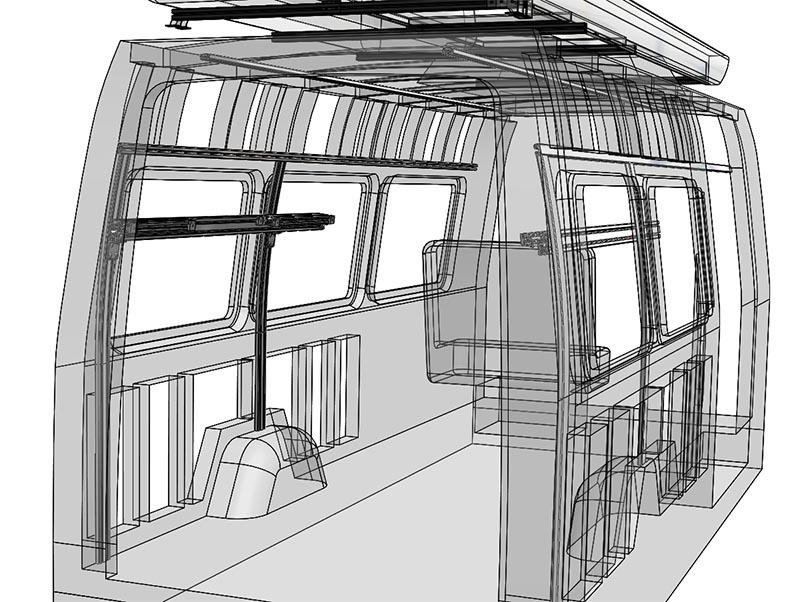

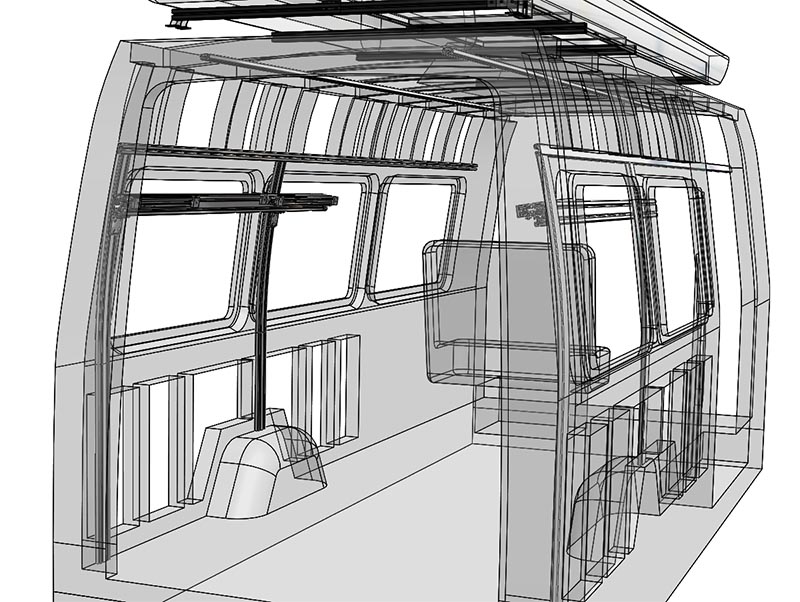

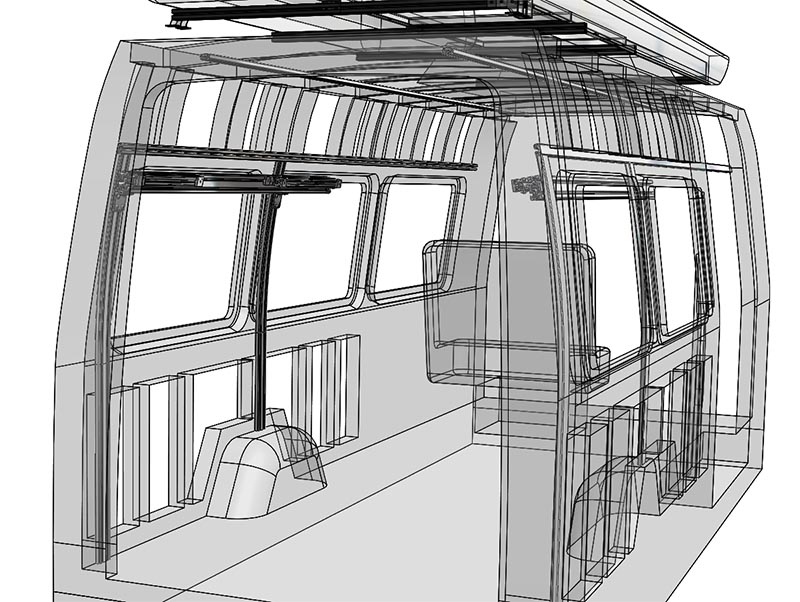

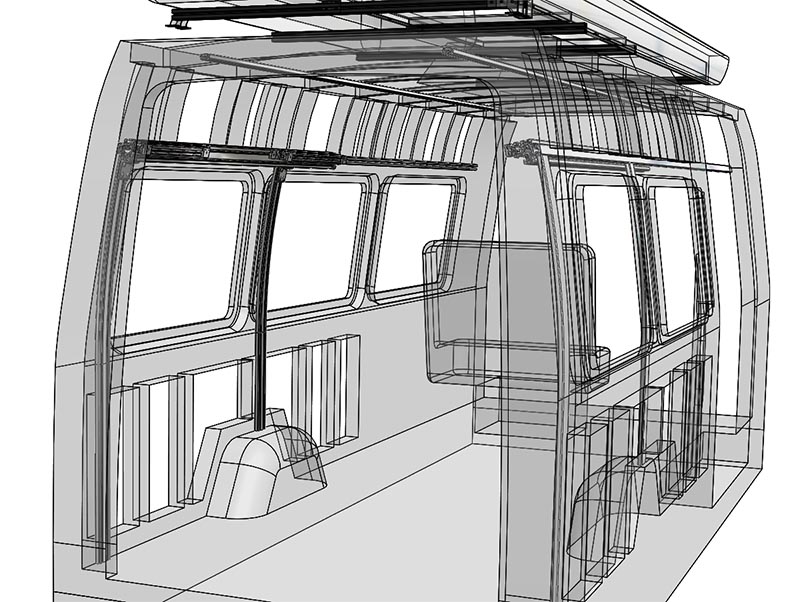

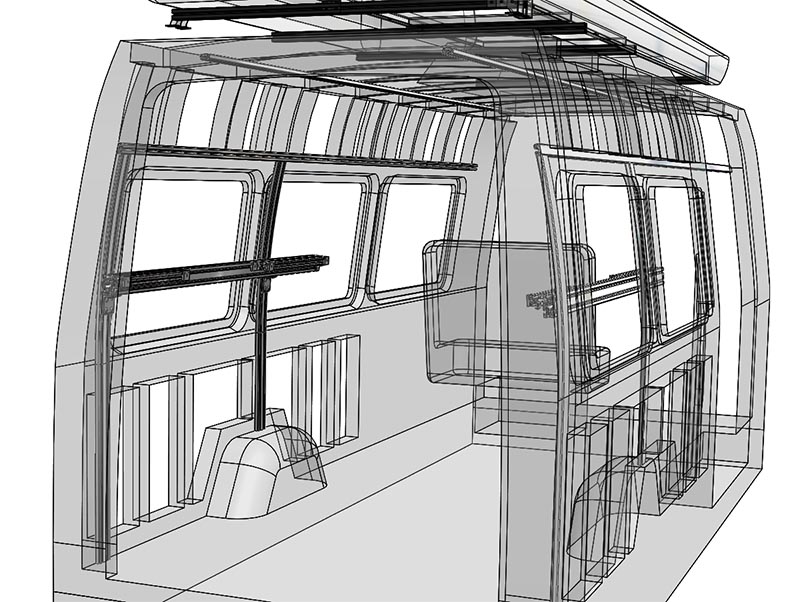

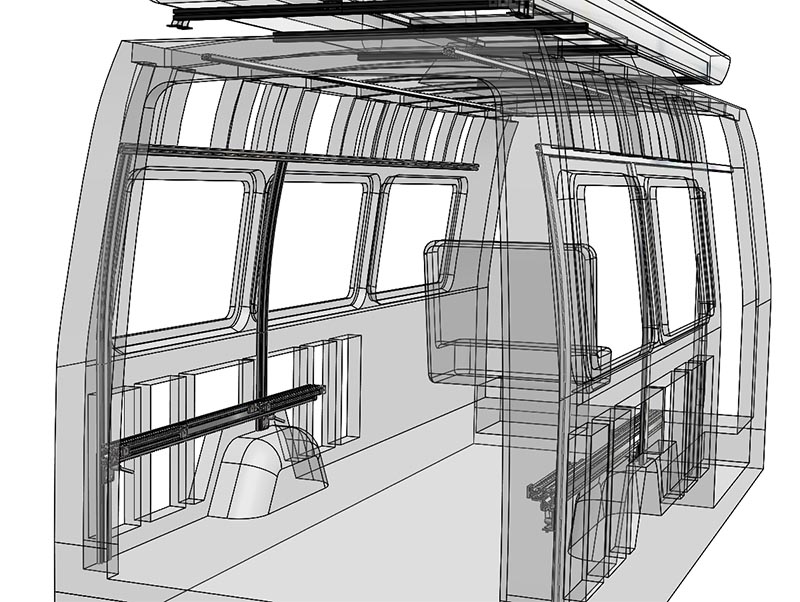

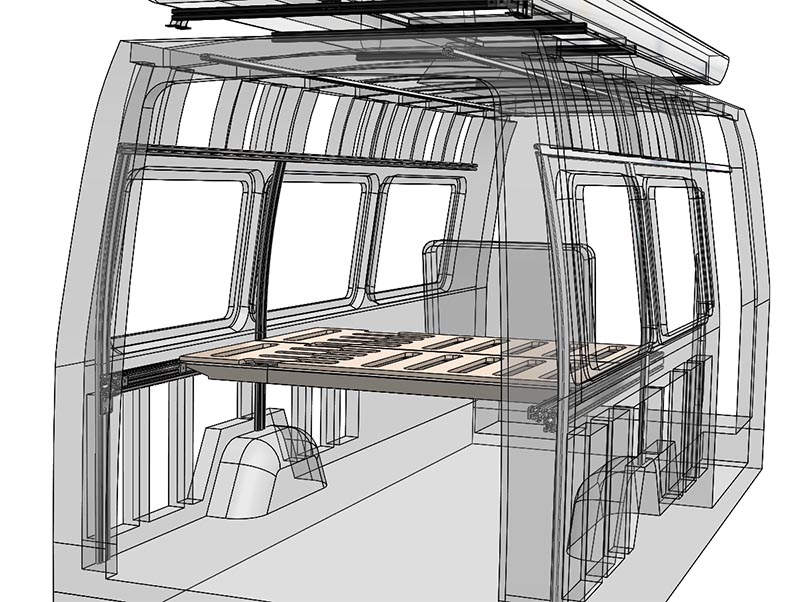

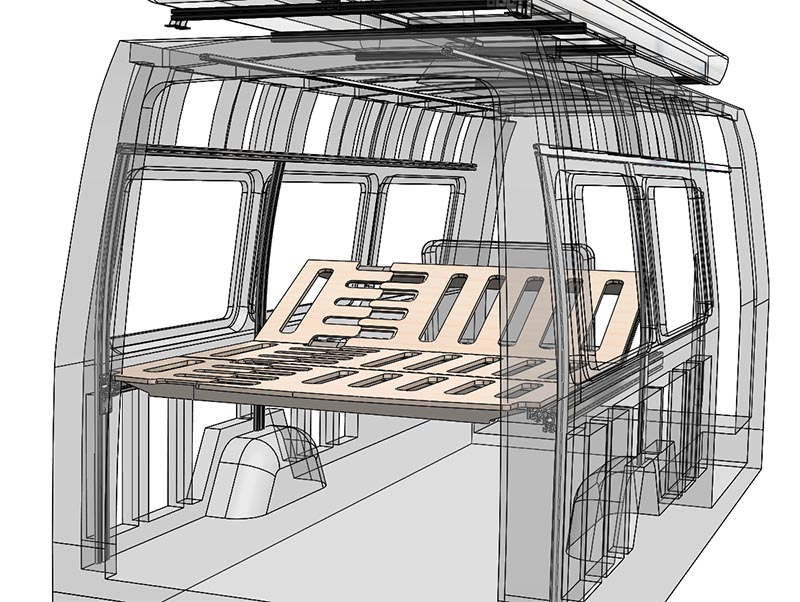

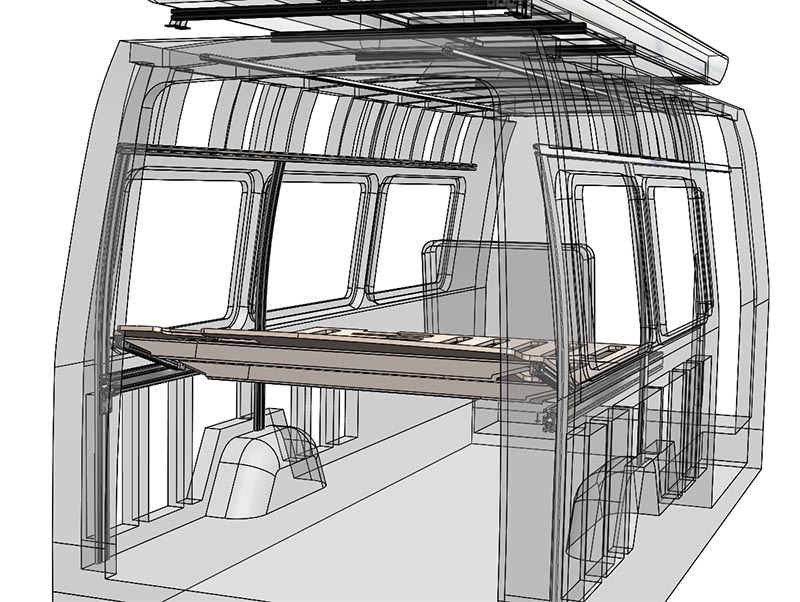

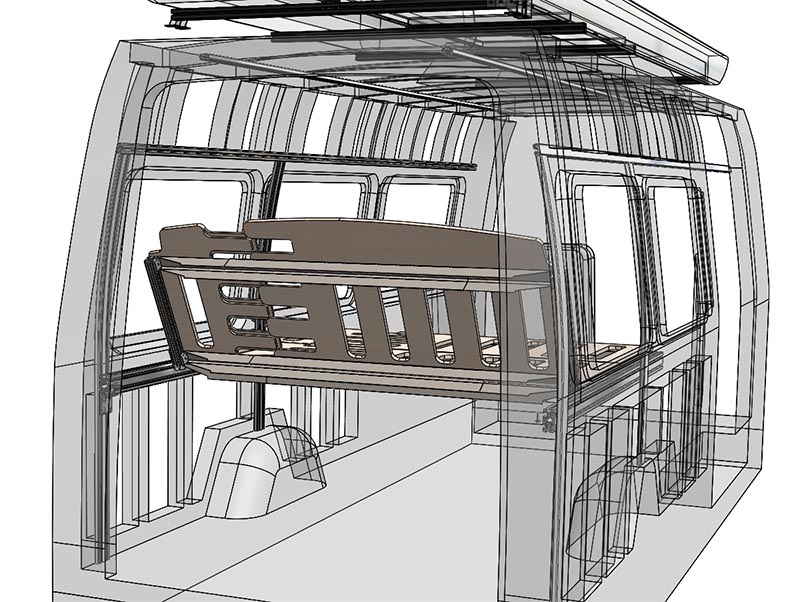

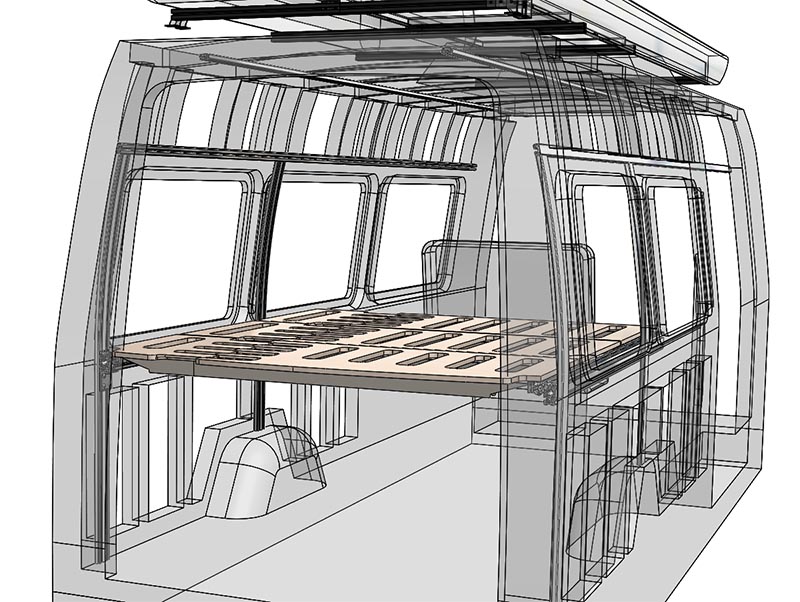

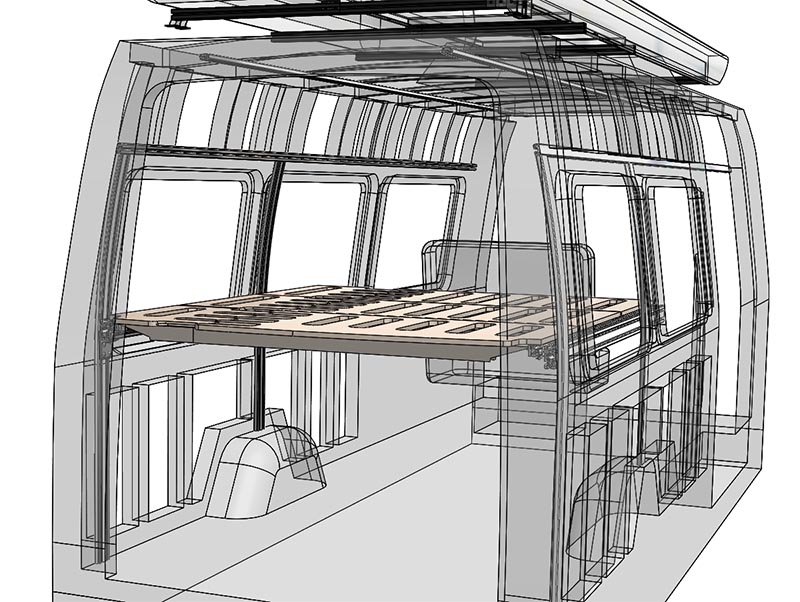

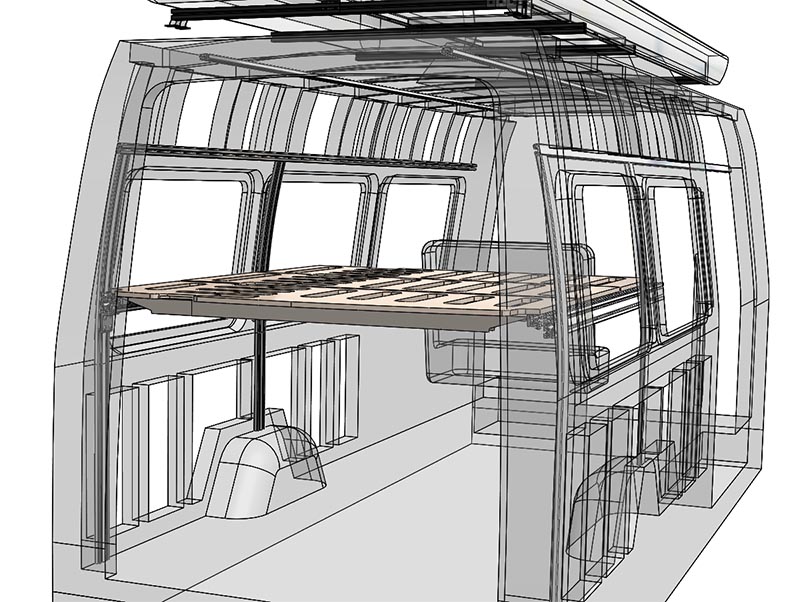

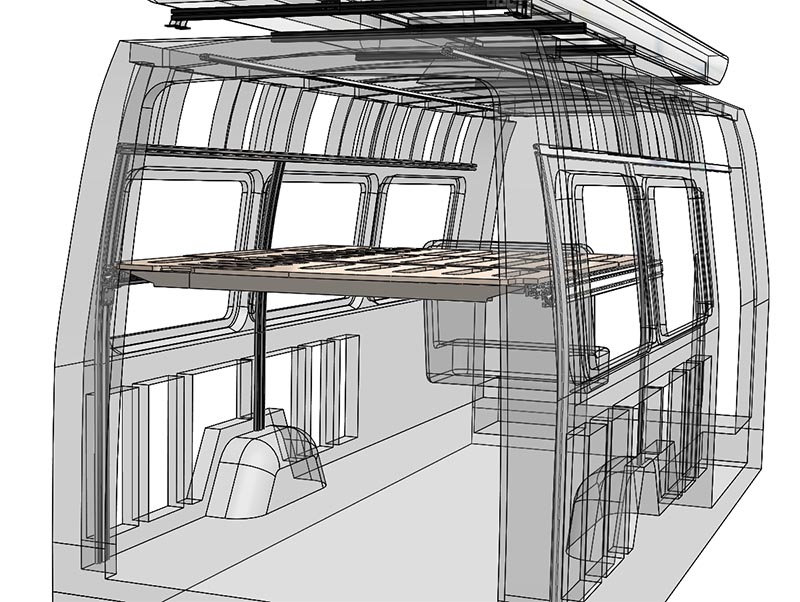

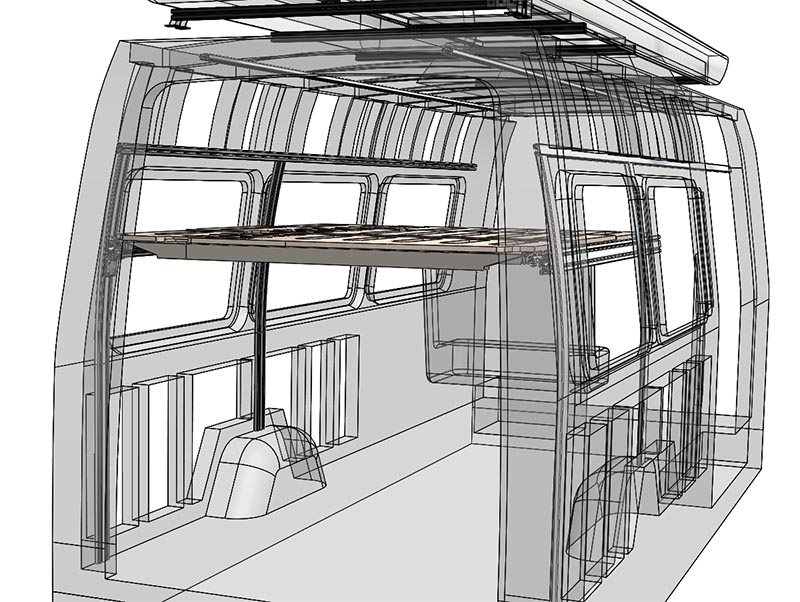

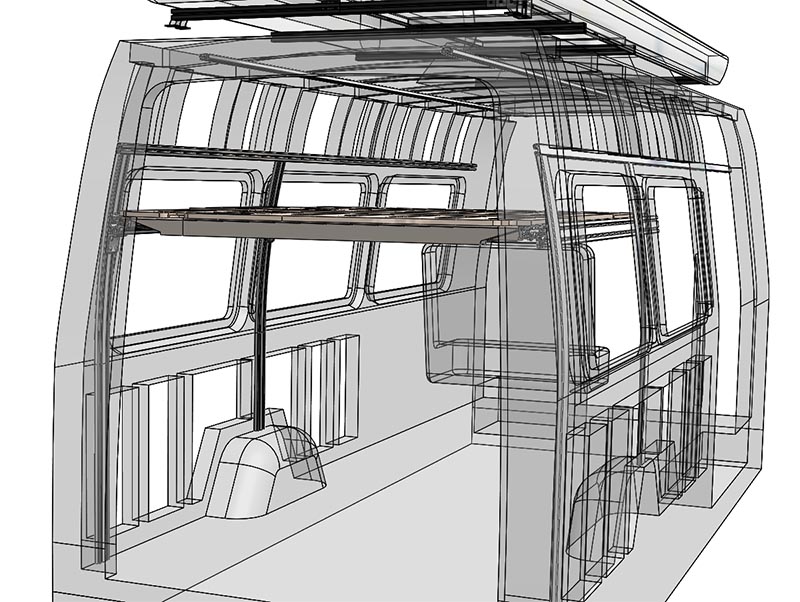

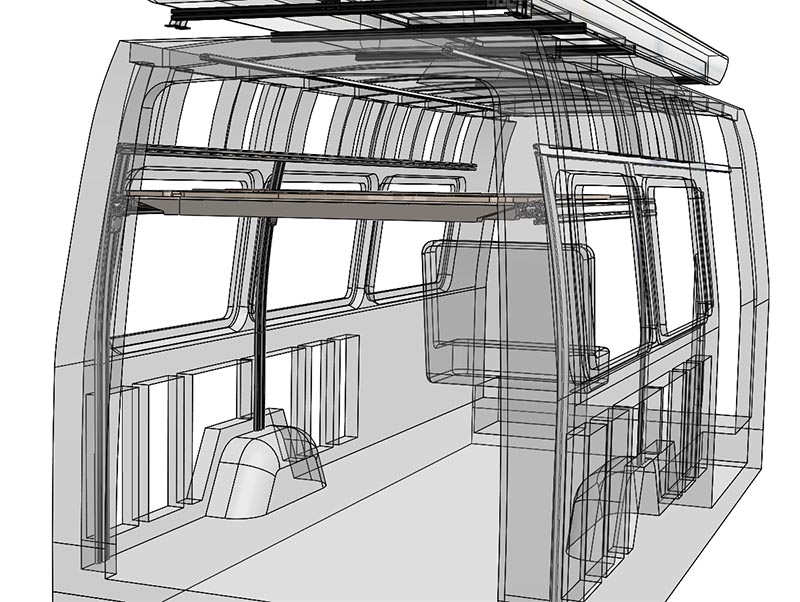

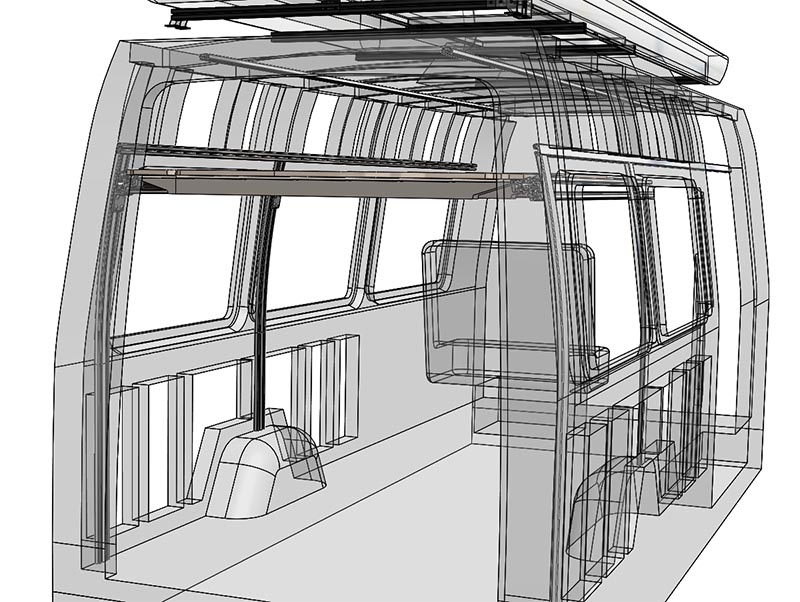

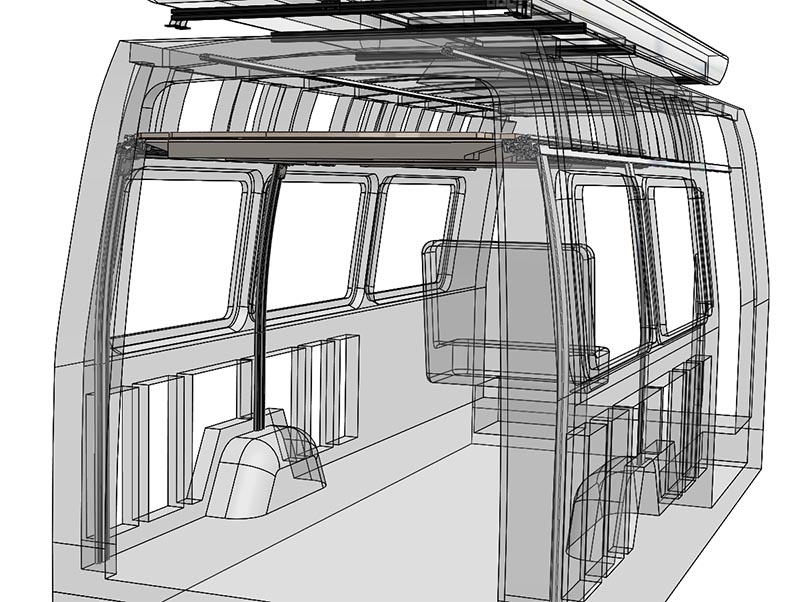

Creating a 3D CAD model was vital

The Mercedes Sprinter has the capacity to easily fit a King size bed. Yes, a King.

We didn’t opt for a king size bed—because that would be ridiculous—and it would take up a tremendous amount of room. We decided on a somewhat less ridiculous, 7” thick Queen size memory foam mattress, from IKEA.

We established the sleeping arrangement to be fore and aft. This makes sense for someone who is 6’ tall. Side-to-side would have been too tight. The window to window measurement is only about 6’2” if you have glass instead of window flares. Having some room above your head is worth it.

At this point, and for the remainder of the buildout, the importance of detailed planning and layout became increasingly clear. Knowing that every inch would need to count when designing the interior of the Sprinter, it was time to get into CAD with the van build.

Using SolidWorks as the primary CAD design tool now for almost 20 years, it was an obvious choice to measure and layout the van in 3D and create an accurate “to scale” model. We also wanted to make sure that we could execute the lower cabinetry efficiently later on during the build.

Defining the Sprinter Conversion Bed Requirements

We like the idea of not having to make the bed every night, like a platform style bed offers. Yet we wanted the versatility to sit upright for hang-out time, unlike a platform. We also wanted to be able to remove the bed—or better yet, move the bed out of the way—in the event we want to haul something large and awesome, like a motorcycle.

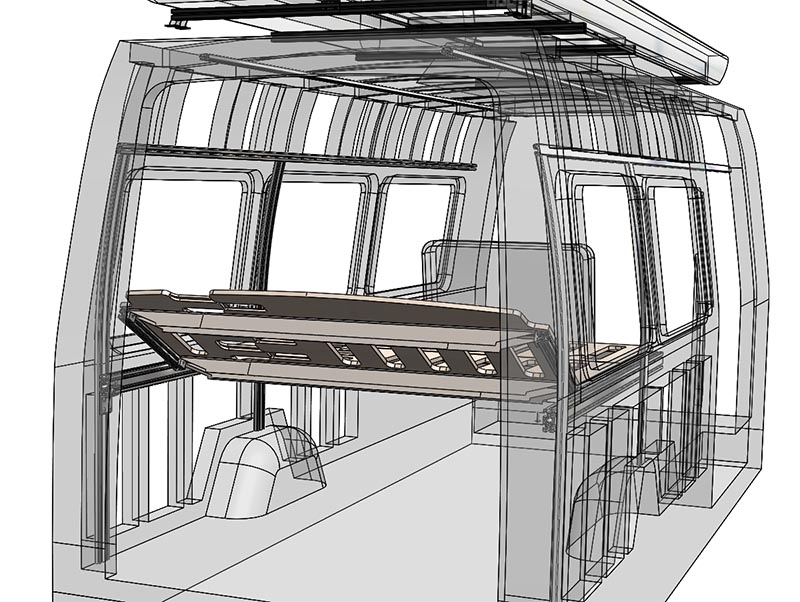

Sliding L-Brackets allow for an adjustable height platform

At Sprinterfest 2017 in Portland, we came across some beautifully crafted bed systems for our inspiration.

Some of these systems were incredibly versatile. But, probably a little too versatile for our needs, and we couldn’t justify the $4500 price points. However, they did provide some inspiration for our bed system design. We went for just enough versatility, at a fraction of the cost… As long as I don’t account for my excessive amount of labor.

A few desirable features kept coming up in our design discussions. The easy access to the underside of the bed, and the ability to remove it infrequently with some level of ease.

Our Sprinter Conversion Bed Requirements:

- Solid and stable as hell

- Adjustable height

- Access under the bed

- Easy to use

Height adjustment capability for storing our bikes underneath the bed, was also of great interest. Another nice-to-have feature that became a requirement was “lounge-ability.” A transforming sofa-bed would be the cherry on top.

Building the Adjustable Bed System for Our DIY Sprinter Conversion

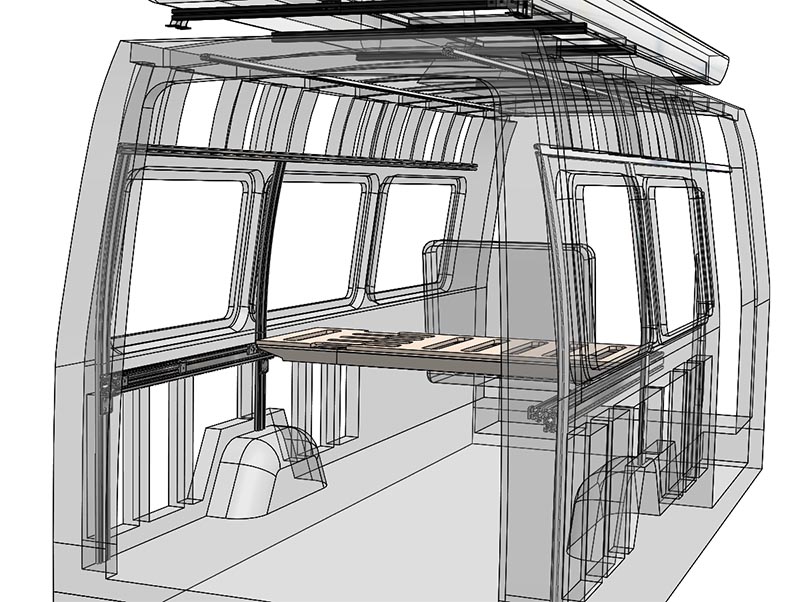

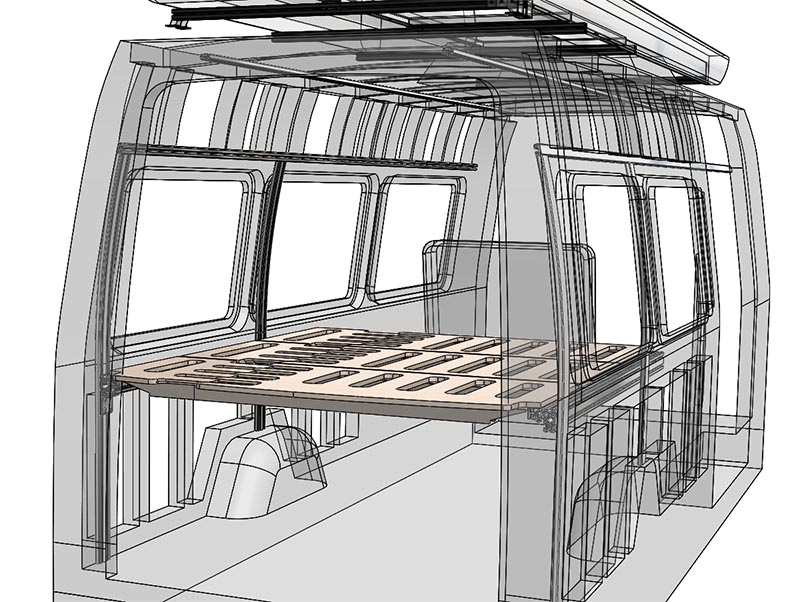

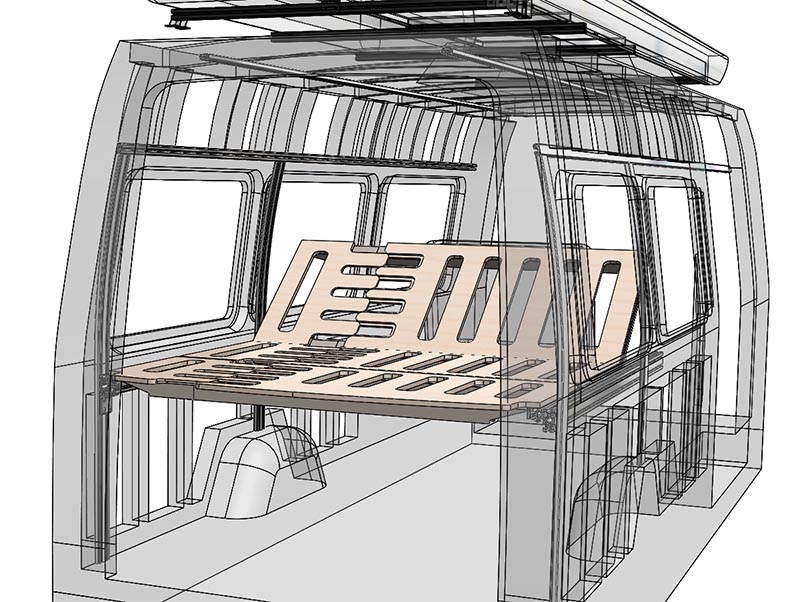

Finger-jointed bed panels shrink and expand as the van narrows and the bed position is manually reinstalled at a different height

Our brainstorming and planning sessions resulted in design with two vertical slot rails on each side of the van, with attached horizontal rails running along each side. This gave us a vertically adjustable rail to rest the bed frame on.

The sides of the van are not flat. The van tapers in from bottom to top, and the vertical side rails needed to be roll bent in order to mount to AND match the curve of the van interior side wall.

This, however, created another design challenge: As you slide the bed system up and down, the width of the bed changes.

To meet this unique requirement, we used telescoping IKEA bed frame struts, and customized finger-jointed panels for the bed platform. This allows the surface that the mattress rests on to collapse in width as the bed frame raises, and expand as it is dropped.

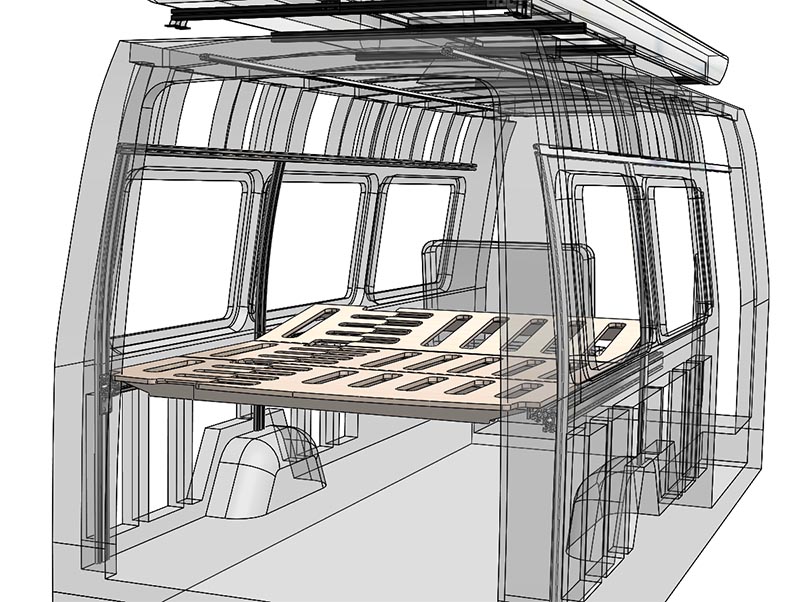

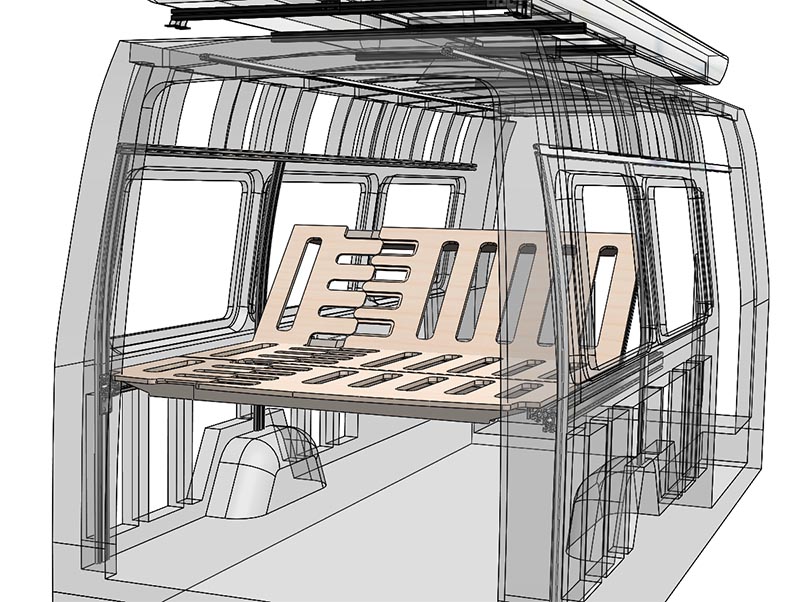

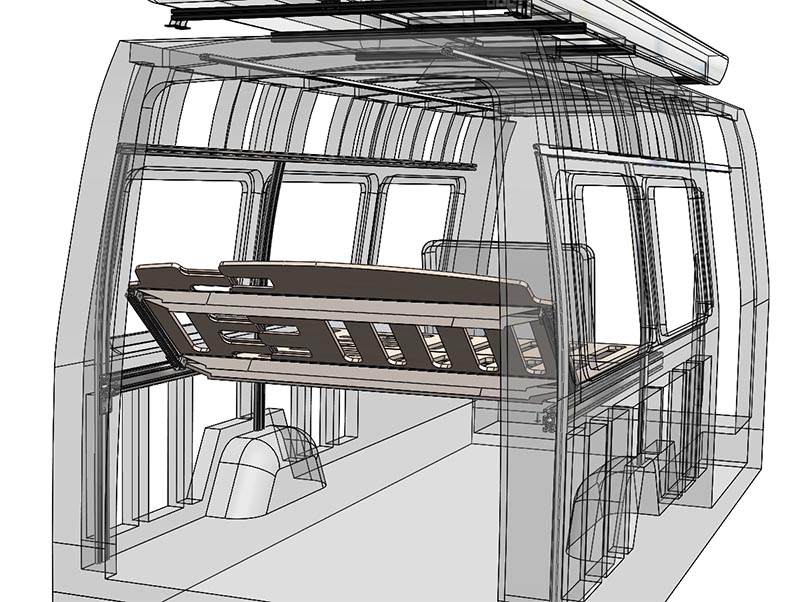

We also split the bed in three sections from toe to head, and can easily remove sections if needed. This feature spawned an additional design opportunity.

We designed the front and rear sections to rest on a pneumatic loaded independent arm that’s fixed to a pivot on the main bed rail mount. As soon as you pick up the edge of the bed, the springs kick in like a truck canopy rear window and lift the head or foot of the bed up.

With one section lifted, you can sit in the bed like a deep futon, facing the interior of the Sprinter or out the back of the van. When both are rotated up—you guessed it—we can have a huge baby crib!

The ability to angle up both the front and back platforms offers fast and easy access to the tremendous amount of storage underneath. Bed, lounge space, baby crib, flexible storage access.

Figuring all of this out took a lot of work. But, that’s where the power of CAD and SolidWorks came into play.

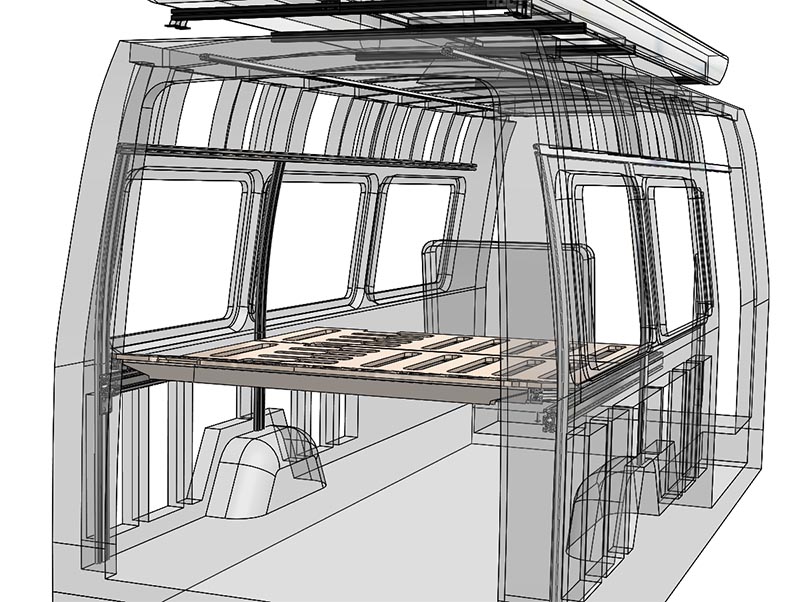

After dialing in all the moving parts in the CAD model, we reached out to Teco Pneumatics again and put in our order for 80/20 extrusion. And waited.

It turns out 80/20 is in high demand, expensive per inch, and their lead times can be long. Especially when you order black anodize material. However, that didn’t stop us from moving forward so we had our CNC router operator produce the bed platforms from apple veneer plywood.

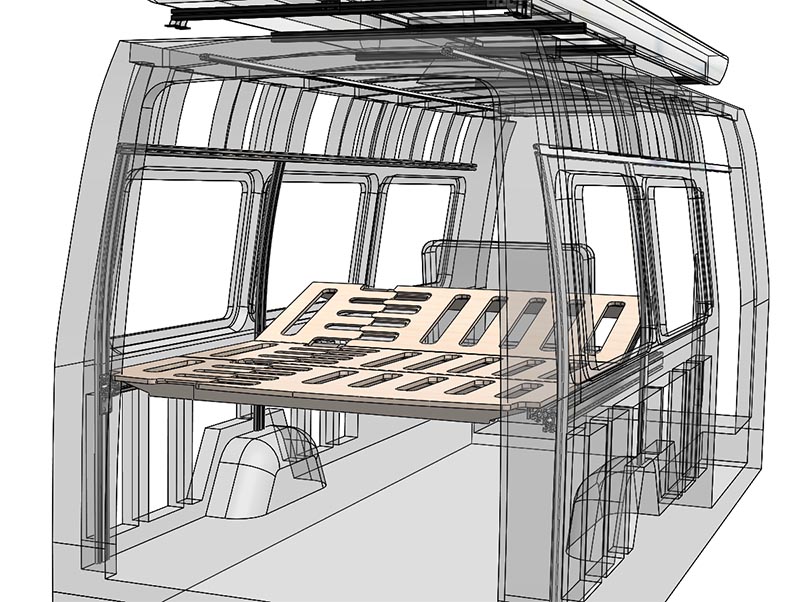

Manufacturing, assembly and test:

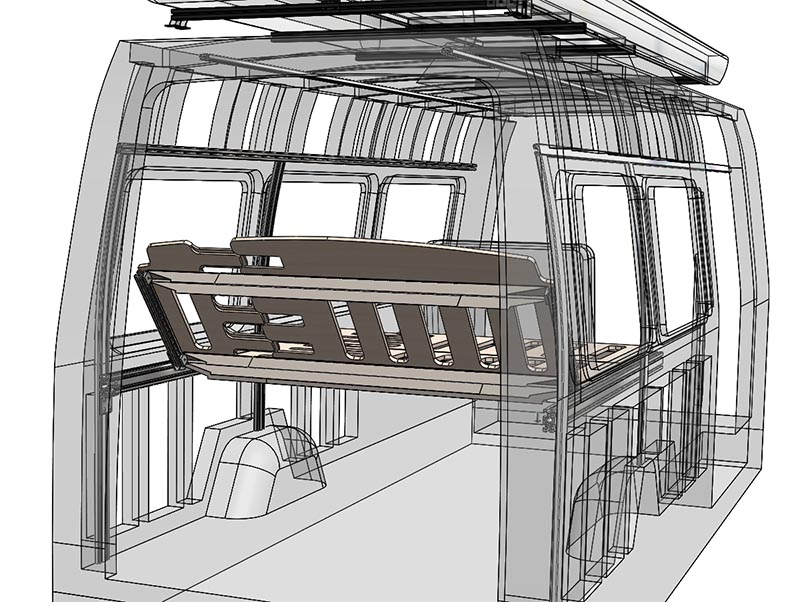

Once everything arrived, things just fit together. And, fit together well.

Assembly was really straightforward. The 80/20 gave us a great deal of flexibility to adjust the exact position of the pneumatics. The prior choice to install T-slots on the walls made installing the bed system a breeze.

However, there was a problem: when picking up the front edge of the bed to rotate it up, it popped out of the mounting clip. So, we reworked it.

The mattress platforms are now secured to the main bed rails with cam levers and pressure plates that have set screws to bite into the IKEA platform rails. Our vendors came to the rescue on that one and made the pressure plates for us to our spec.

Investing time and resources in the component that takes up the greatest amount of square footage in the van was a good call. The bed system is incredible. When we don’t need the bed at a height to store the bikes underneath, we quickly lower it to a more comfortable height.

Now it’s time to install cabinets! Stay tuned for our next DIY Sprinter conversion update where we tackle the cabinetry.

Some of the above links will take you to Amazon, and as an Amazon Associate CreatID, Inc. will earn revenue from qualifying purchases.

In Hindsight:

Although unavoidable and unforeseen, we didn’t realize the height would be as much of an issue. If you put large bikes under the bed, the bed gets very tall. This is not good for our toddler wanting to get off the bed by himself. And then get back on, and off, and…you get the point. Even with this problem though, we were able to get the bed at a reasonable height, with the front and rear wheels removed from the bikes and secured upside down.

The baby crib worked. For a day. Then our toddler figured out how to climb over it, which made the idea even worse than falling off the edge of the bed. Especially out the back. And that fall is a doozy.

I’ll be installing stronger pneumatics in order to support the weight of an adult when it’s in the deep futon configuration. The current ones are just a little weaker than I would like. Having quick access to the front and rear underside of the bed with ‘liftable’ hinged panels is fantastic. A very valuable function of the system. Almost more so than the sofa feature.

A lighter and smaller 80/20 profile would be fine—they are strong. They get heavy and sizeable, quickly.

Regardless of all of these comments, I will be remaking the bed. Without a doubt it’s a great product, but I’m selling it. In it’s place I’ll be fabricating a new bed system where the front will drop into a seating position and allow for a table and some hangout room, while still having a rear panel to lay on top of.